The expiration date setting of curry

Best before date

・”Best before” is an approximate date by when the product should be consumed to enjoy it at its best. It does not mean that the product is unsafe to eat after this date.

・In the case of curry (curry powder and curry roux), since they have relatively low moisture content, exceeding the best before date does not typically lead to a significant decline in flavour or cause health issues.

・The “best before” or “best by” date on a product is typically set by the manufacturer as the date until when the product is expected to maintain its optimal flavour, colour, texture and overall quality as intended by the manufacturer.

・The expiration date is determined for the product remaining in an unopened state.

Changes in taste over time

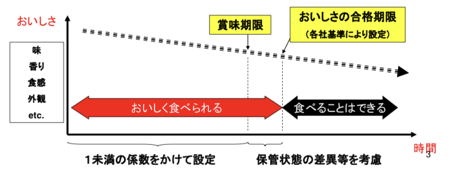

Many foods lose their freshness and taste as time passes. The deliciousness of curry gradually decreases over a period of several months to two years.

※ The determination of the acceptable period for taste is based on storage tests.

※ The criteria for determining the acceptable period for taste may vary to some extent depending on the manufacturer and the type of curry.

※ The expiration date (best before date) is determined with some margin for safety, taking into consideration differences in storage conditions and other factors. (Based on the “Guidelines for Setting Food Expiry Dates” by the Consumer Affairs Agency)

Plan for Storage Test

Step 1: Tentatively set the expiration date, considering similar products and planned sales periods.

Step 2: Determine the duration of the storage test, taking into consideration a certain level of safety.

Step 3: Establish storage conditions based on the processes, environment and product characteristics until it reaches the consumer.

Step 4: Determine the evaluation criteria for taste.

Step 5: Determine the appropriate timing for measurements to capture changes in taste.

Analysis example of storage testing

In storage testing, the following confirmations are made over time.

● Deliciousness (general)

Taste

Sensory Evaluation, Lipid Analysis, Moisture Content Analysis

Is the change in taste within acceptable limits? Has the lipid content deteriorated? Is there any bad taste present?

Aroma

Sensory Evaluation

Is the reduction in aroma within acceptable limits? Are there any changes in aroma? Is there any unusual odour present?

Product appearance

Sensory evaluation (shape, colour)

Has the shape changed? Are there any cracks or peeling? Has the colour faded? Has there been any browning?

● Safety

Microbiological analysis

Total viable count, mould and yeast (causes of spoilage)

Fat analysis

Oxidation of fats

※Analysis conducted by individual manufacturers or external analysis institutions.

※Sensory evaluation conducted by multiple in-house inspectors.

5 changes in the deliciousness of curry

Curry powder

・Volatile aroma compounds may evaporate (weakening the aroma).

・The aroma may change.

Curry roux

・Volatile aroma compounds may evaporate (weakening the aroma).

・Hygroscopicity can accelerate the degradation and discolouration of fats.

・Exposure to high temperatures and direct sunlight can lead to the degradation of fats and changes in flavour.

Guidelines for storing curry

Please follow the storage instructions (temperature, etc.) indicated on the packaging.

Since curry roux can become soft and deform at high temperatures, please store it in a cool place to avoid high temperatures. Once high temperatures have deformed curry roux, cooling it again may change its original appearance. However, there will be no difference in taste or aroma.

○ Avoid high temperatures, humidity and direct sunlight

If using a container with excellent sealing properties, such as one designed for low moisture activity and specific types of fats, long-term storage of curry roux is possible. However, if left in conditions with high temperatures, high humidity, or direct sunlight for an extended period, the aroma may weaken (the taste may appear milder), and there may be changes in flavour due to oxidation.

Please be aware that the interior of a car can become extremely hot.

When stored at high temperatures, curry roux may become soft as described above, and the fats within the roux may rise to the surface and solidify upon cooling, resulting in a whitish appearance (known as blooming). However, even if this happens, it can still be enjoyed. After opening, please store it in a cool, low-humidity environment and consume it as soon as possible.

(Reference 1) About curry powder

Explanation of curry powder

・Curry powder is created by grinding, mixing, roasting, storing and sifting various spices over a certain period, resulting in uniform curry powder.

・There are generally around 20 to 30 types of spices used.

・Since curry powder has low moisture content, as long as it is stored in appropriate packaging and in normal temperature and humidity conditions, there should be no microbial growth.

・Some of the essential oil components it contains exhibit antioxidant properties.

(Reference 2) About curry roux

Explanation of curry roux

・Curry roux is made by sauteing starches like wheat flour in edible oils and then heating and mixing them with curry powder, dairy products, and other seasonings as needed. It is then cooled to create the final product.

・Curry roux has very low moisture content, so as long as it is stored in appropriate packaging and in normal temperature and humidity conditions, there should be no microbial growth

・It primarily uses solid fats that are less prone to oxidation, so it is less susceptible to oxidation. However, if stored in conditions with high temperatures and high humidity, the fats can progressively oxidise, affecting the aroma, taste and colour. Evaluating the state of fat oxidation is important.

(Reference 3) About sensory evaluation

Sensory evaluation is the process of assessing the quality of raw materials, products, etc., under specific conditions using the five senses, including sight, taste, smell and touch.

• Under appropriate conditions, qualified inspectors quantify the evaluation using appropriate methods.

• Evaluation criteria typically include the four aspects mentioned earlier: “taste”, “aroma”, “texture” and “appearance”.

• Specific evaluations are carried out in each category, comparing the product to one made immediately after production, typically using a multi-stage scale (e.g. 5 stages), and an overall judgment is made.

(Reference 4) Best before date and Use by date

Best before date

This is the date until which the product is expected to maintain all of its intended qualities when stored under specified conditions. Even beyond this date, the product may still retain these qualities.

Definition: The date indicating the year and month until when, under the defined storage conditions, the product is expected to maintain all of its intended qualities. However, even after this date, the product may still retain these qualities.

The defined storage conditions refer to the storage method indicated on the product label.

Use by date

It is recommended not to consume the product after the expiration date has passed. (Generally, it applies to food items where quality changes significantly due to freshness.)

• Definition: It refers to the date, expressed as a year and month, which indicates the expiration date when, if stored according to the specified method, there is no foreseeable risk of it being unsafe due to spoilage or any other deterioration in quality.

From the Consumer Affairs Agency website.

Trans Fat Reduction Initiative by the Curry Association

In 2011, in response to the Consumer Affairs Agency’s “Guidelines on Disclosure of Trans Fatty Acids”, the All Japan Curry Industrial Cooperative Association confirmed an agreement during its board meeting to individually adjust and reduce trans fatty acids content. In 2014, with discussions around “trans fatty acids” as part of the “Food Labelling Standards Revision” and the FDA’s deliberations, the association once again considered this matter. The association undertook to assess the current status of trans fatty acid content in the curry roux produced by its member companies and consider appropriate measures as an association. First, the association initiated surveys among its members to confirm the levels of “trans fatty acids” and the usage of “partially hydrogenated oils” in their curry roux products. Based on the survey results, the Technical Committee confirmed its commitment to continue working on the reduction of “trans fatty acids” and took the following specific actions:

1) It is essential for our members to understand the levels of trans fatty acids in their products. For companies that have not yet calculated these values, we will provide a formula for calculation and request confirmation based on the calculated values.

2) As part of our efforts to reduce trans fatty acids, we recommend measures for the use of “low-trans fatty acid oils and fats” and provide advice in this regard. In 2015, we conducted another survey on the content of trans fatty acids and strategies for its reduction. This resulted in a significant reduction, with consumer products containing 0.33g per 100g and 0.071g per serving, which is one-tenth of the levels observed in previous years (2007-2014). A similar reduction has been achieved for commercial use products.

Results of the All Japan Curry Industry Cooperative’s Fact-finding Survey in September 2015:

Average Trans Fatty Acid Content:

- September 2015 Survey: 0.33g per 100g, 0.071g per serving

- Previous Period (2007-2014): 3.68g per 100g, 0.81g per serving

(Note: Trans fatty acid content per serving (g) = Curry Roux Amount per serving (g) × Trans fatty acid ratio in the product (%))